DIN 16903 Rändelgewindeeinsätze

Wir sind ein weltweit renommierter Hersteller von Rändelgewindeeinsätzen nach DIN 16903 zum Umspritzen. Wir fertigen verschiedene Arten von Einsätzen nach internationalen Normen, darunter DIN und viele andere nach Kundenanforderungen. Wir verfügen über ein erfahrenes Team und nutzen moderne Fertigungsmaschinen, um präzise Rändelgewindeeinsätze nach DIN 16903 herzustellen. Wir verwenden die besten Rohstoffe zur Herstellung hochwertiger Gewindeeinsätze nach DIN 16903, die auf Langlebigkeit, Präzision und Zuverlässigkeit ausgelegt sind. Rändelgewindeeinsätze nach DIN 16903 sind auf Qualität, Leistung und Wert ausgelegt.

Wir wissen, dass jedes Projekt einzigartige Anforderungen hat. Basierend auf kundenspezifischen Anforderungen ist unser Entwicklungs- und Fertigungsteam bereit, mit uns zusammenzuarbeiten und kundenspezifische Rändelgewindeeinsätze nach DIN 16903 herzustellen. Von der Materialauswahl bis hin zu Designänderungen stellen wir mit unseren personalisierten Lösungen die Kundenzufriedenheit sicher. Wir bieten Rändelgewindeeinsätze nach DIN 16903 in verschiedenen Materialien, Ausführungen, Größen und Gewinden an, wie z. B. ISO-metrisch (MM-Gewinde), BSP & BSPT (Parallel- und Kegelgewinde), NPT-Gewinde, BSW-Gewinde (Zoll), BSF-Gewinde, UNC-, UNF-Gewinde, BA-Gewinde und alle Gewinde nach Normen und Sonderausführungen. Alle unsere Produkte, einschließlich DIN 16903, sind zu wettbewerbsfähigen Preisen erhältlich.

Material:

- Brass : C3604, Brass IS-319 Type-1, C36000, CuZn39Pb3, CuZn39Pb2, CuZn38Pb2, CuZn38Pb1.5

- Steel : Steel EN1A/EN1AL,12L14, 11SMNPB30, 9SMNPB28

- Aluminium : EN AW-6060, EN AW-6061, EN AW-6082

- Spezielle Metallwerkstoffzusammensetzung nach Kundenwunsch.

Verfügbarkeit:

In India as well as USA, UK, Australia, Germany, France, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Spain, Sweden, and other European counties.

Oberflächenveredelung:

Jegliche Veredelung/Beschichtung gemäß Kundenwunsch.

Hauptmerkmale der Rändelgewindeeinsätze nach DIN 16903:

Anwendungsgebiete der Rändelgewindeeinsätze DIN 16903:

Warum sollten Sie sich für unsere Gewindeeinsätze nach DIN 16903 entscheiden?

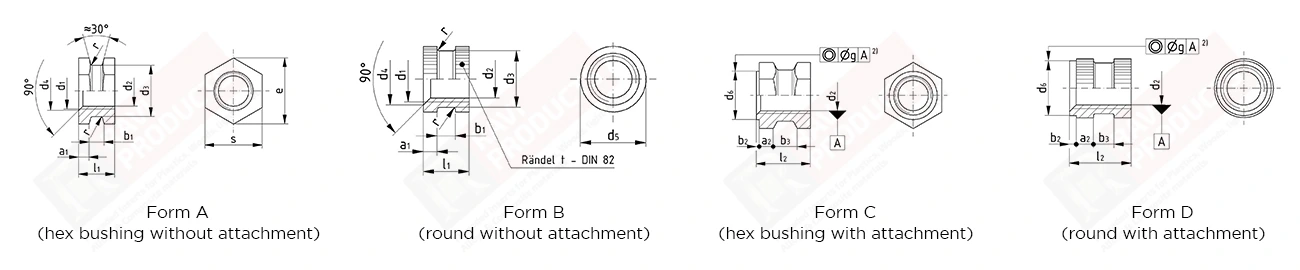

Forms A–D

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | B / D | A / B / C / D | A / C | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 0.8 | 0.9 | 0.9 | 1 | 1.2 | 1.6 | 1.8 | 2 | 3 | 3.5 | |

| a2 | 0.9 | 1 | 1.2 | 1.6 | 1.8 | 2 | 2.5 | 4 | 4 | 5 | |

| b1 | 0.8 | 0.8 | 1.2 | 1.4 | 1.4 | 1.8 | 2.4 | 4 | 4 | 5 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 0.8 | 1 | 1.2 | 1.4 | 1.4 | 2.5 | 3 | 4 | 6 | 7 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | – | – | – | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h12 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h12 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | – | – | – | |

| s | ≈ | – | – | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 |

| e | ≈ | – | – | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

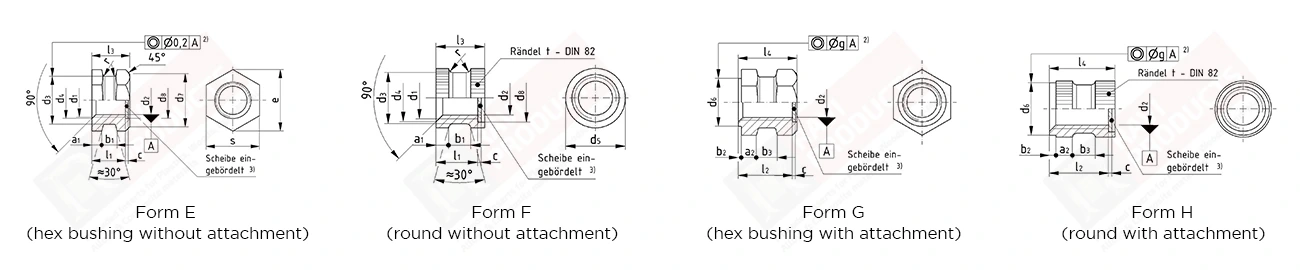

Forms E–H

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | F / H | E / F / G / H | E / G | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.8 | 2.5 | 3 | 3.5 | |

| a2 | 1 | 1.2 | 1.2 | 1.5 | 1.5 | 2 | 2.5 | 3.5 | 4 | 5 | |

| b1 | 1.2 | 1.5 | 1.5 | 1.8 | 2.2 | 2.5 | 3.2 | 3.8 | 4.5 | 5.5 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.5 | 1.6 | 1.8 | 2.2 | 2.5 | 3 | 3.5 | 4.5 | 6 | 7 | |

| c | 0.32 | 0.32 | 0.32 | 0.54) | 0.54) | 0.54) | 0.54) | 15) | 15) | 15) | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 124) | 154) | 184) | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | – | – | 4.2 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| d83) | D11 | 2.6 | 2.8 | 3.2 | 3.8 | 4.5 | 6 | 7 | 9 | 11 | 13 |

| e | ≈ | – | – | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h14 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h12 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h12 | 3.1 | 3.4 | 3.8 | 4.5 | 5 | 6 | 7 | 9.5 | 11.5 | 13.5 |

| l4 | h12 | 4.3 | 4.8 | 5.3 | 6.5 | 7 | 8.5 | 10 | 13.5 | 16.5 | 19.5 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| s | – | – | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | – | – |

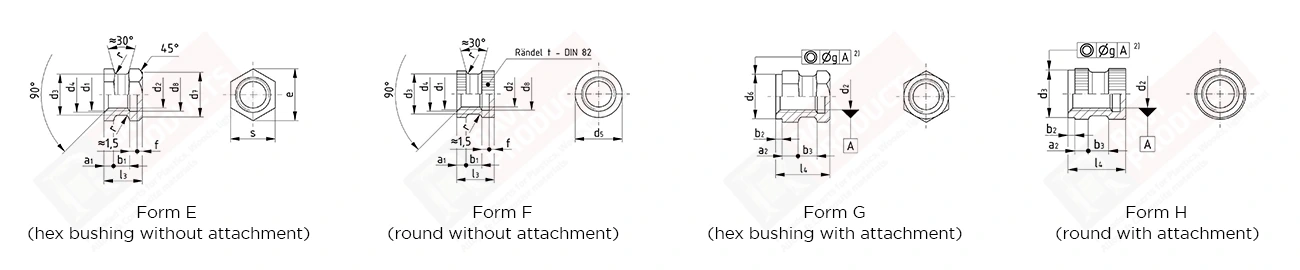

Forms E–H (similar)

| Threaded bushings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | E / F / G / H | E / G | ||||||

| Thread d1 (6H) | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M10 | ||

| a1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.8 | 2.5 | Possible upon inquiry | ||

| a2 | 1.2 | 1.5 | 1.5 | 2 | 2.5 | 3.5 | |||

| b1 | 1.5 | 1.8 | 2.2 | 2.5 | 3.2 | 3.8 | |||

| b2 | 1 | 1 | 1 | 1 | 1 | 1 | |||

| b3 | 1.8 | 2.2 | 2.5 | 3 | 3.5 | 4.5 | |||

| f | (Production-related min. gradient x 1.5 / must be clarified before ordering) |

||||||||

| d2 | H11 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | ||

| d3 | h12 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | ||

| d4 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | |||

| d51) | 4.2 | 5 | 5.5 | 7 | 8 | 12 | |||

| d6 | h11 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | ||

| d7 | 4.2 | 5.5 | 6 | 7 | 9 | 11 | |||

| d8 | + 0.3 | 3 | 3.5 | 4 | 5 | 6 | 8 | ||

| g | h14 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | ||

| l3 | h12 | 3.8 | 4.5 | 5 | 6 | 7 | 9.5 | ||

| l4 | h12 | 5.3 | 6.5 | 7 | 8.5 | 10 | 13.5 | ||

| r | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | |||

| t | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | |||

| s | 5 | 5.5 | 6 | 7 | 9 | 11 | |||

| e | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | |||

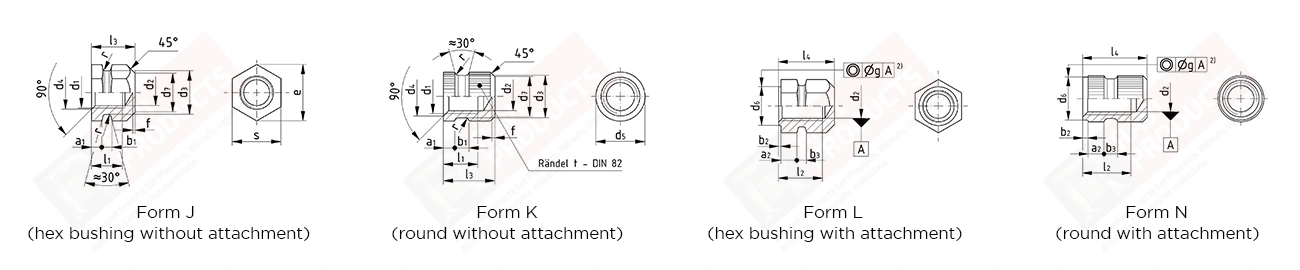

Forms J–N

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | K / N | J / K / L / N | J / L | |||||||

| Thread d1 (6H) | M 24 | M 2.54 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1.2 | 1.4 | 1.5 | 1.5 | 1.8 | 2 | 2.8 | 3.5 | 4 | |

| a2 | 1.2 | 1.5 | 1.6 | 2 | 2 | 2.5 | 3 | 4.2 | 5.5 | 6.5 | |

| b1 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 2 | 2.5 | 3 | 3.5 | 4 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 2 | 2.5 | 3 | 3.5 | 4 | |

| d23) | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | ≈ | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | – | – | – |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | 3 | 3.4 | 3.8 | 4.5 | 5 | 6 | 7 | 9 | 12 | 15 | |

| f | + 0.24) | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| l1 | h144) | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h144) | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h124) | 3.8 | 4.2 | 4.8 | 5.5 | 6.5 | 7.6 | 9 | 12 | 14.2 | 17 |

| l4 | h124) | 5 | 5.6 | 6.3 | 7.5 | 8.5 | 10.2 | 12 | 16 | 19.2 | 23 |

| s | – | – | – | – | 6 | 7 | 9 | 11 | 14 | 19 | |

| e | ≈ | – | – | – | – | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

| g 4) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| r 4) | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t 4) | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | – | – |

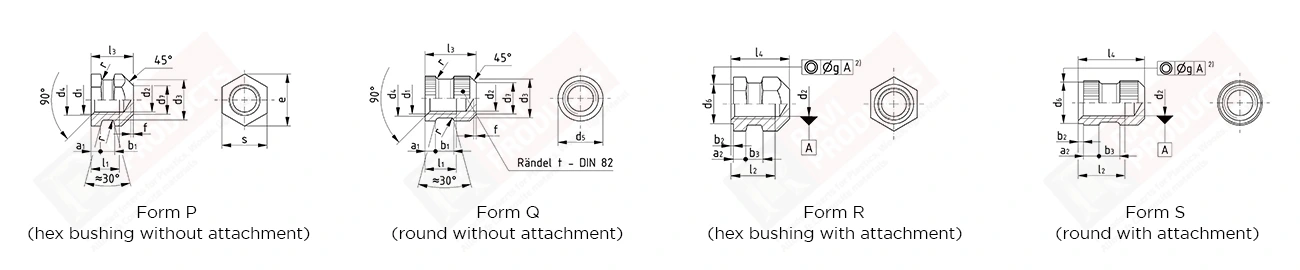

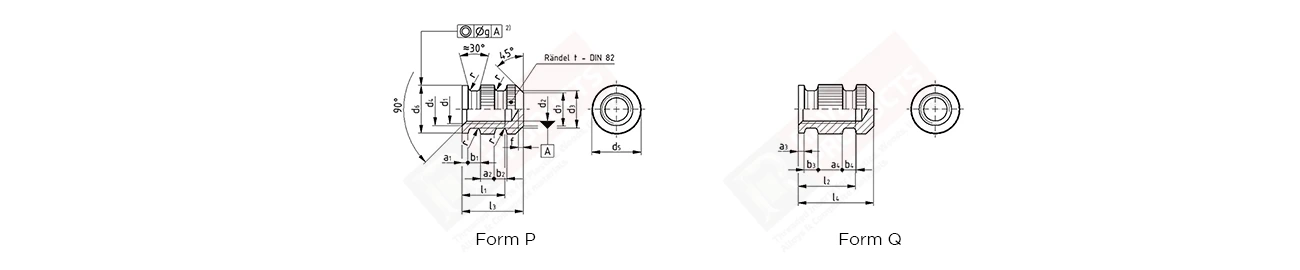

Forms P–S

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | Q / S | P / Q / R / S | P / R | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1.2 | 1.4 | 1.5 | 1.5 | 1.8 | 2 | 2.8 | 3.5 | 4 | |

| a2 | 1.2 | 1.5 | 1.6 | 2 | 2 | 2.5 | 3 | 4 | 5 | 5 | |

| b1 | 1.2 | 1.5 | 1.8 | 1.8 | 2.5 | 3 | 3.5 | 4.5 | 5 | 6 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.6 | 1.6 | 1.8 | 2 | 2.8 | 3.5 | 4 | 5.5 | 6 | 7 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | – | – | – | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | 2.5 | 2.5 | 2.8 | 3.5 | 4 | 5 | 6 | 7 | 10 | 12 | |

| f | + 0.2 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h14 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h14 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h12 | 4 | 4.6 | 5.5 | 6 | 7 | 8.3 | 9.8 | 12.6 | 15 | 17.8 |

| l4 | h12 | 5.2 | 6 | 7 | 8 | 9 | 10.8 | 12.8 | 16.6 | 20 | 23.8 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | – | – |

| s | – | – | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| e | – | – | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 | |

Forms T–U

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | T | T / U | U | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1.2 | – | – | – | |

| a2 | 1 | 1.1 | 1.3 | 1.6 | 1.8 | 2.2 | 2.8 | – | – | – | |

| a3 | – | – | – | – | 1 | 1 | 1.2 | 1.5 | 1.5 | 2 | |

| a4 | – | – | – | – | 4 | 4.5 | 5 | 6 | 8 | 10 | |

| b1 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.2 | 2.7 | – | – | – | |

| b2 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.2 | 2.7 | – | – | – | |

| b3 | – | – | – | – | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| b4 | – | – | – | – | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.5 | 4 | 4.6 | 5.3 | 6.6 | 7.8 | 10.5 | 13 | 15.7 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 4.5 | 5 | 5.5 | 6 | 7 | 9 | 10 | 12 | 15 | 18 | |

| d6 | h11 | 4.5 | 5 | 5.5 | 6 | 7 | 9 | 10 | 12 | 15 | 18 |

| d7 | 3.4 | 3.6 | 3.8 | 4.5 | 5 | 6 | 7 | 9 | 12 | 15 | |

| f | +0.2 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| l1 | h14 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | – | – | – |

| l2 | h14 | – | – | – | – | 8 | 10 | 12 | 16 | 20 | 24 |

| l3 | h12 | 5.2 | 6 | 7 | 8 | 9 | 10.5 | 12.8 | – | – | – |

| l4 | – | – | – | – | 11 | 13.3 | 15.8 | 20.6 | 25 | 29.8 | |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Wir sind bestrebt, erstklassige DIN 16903 Rändelgewindeeinsätze und außergewöhnlichen Service zu liefern, um Ihren Geschäftsanforderungen gerecht zu werden. Kontaktieren Sie uns noch heute, um Ihre Anforderungen zu besprechen, oder fordern Sie ein Angebot für DIN 16903 Rändelgewindeeinsätze an.