Metal Threaded Inserts: Revolutionizing Fastening Solutions in the Automotive Sector!

In the fast-evolving automotive industry, where precision, durability, and efficiency are paramount, metal threaded inserts have emerged as a game-changing solution. These small yet powerful components provide unmatched strength, corrosion resistance, and secure fastening in critical applications, making them indispensable for modern automotive manufacturing. Ravi Products, a trusted name in innovative fastening technologies, is at the forefront of this revolution, offering high-quality metal threaded inserts that cater to the industry’s stringent demands.

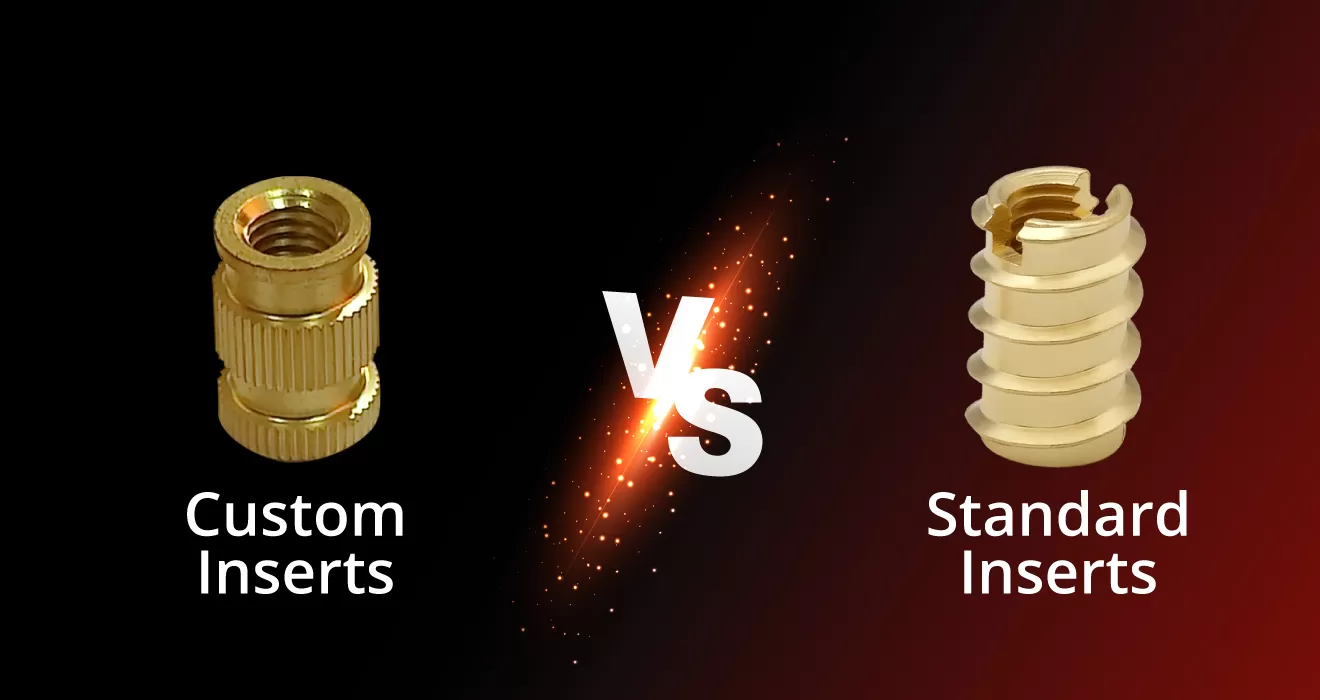

Custom Metal Threaded Inserts

Threaded inserts are cylindrical, tube-shaped metal components featuring both internal and external threads. Designed to reinforce or repair damaged threads in metalwork, they offer a reliable threaded receptacle for bolts, screws, and other fasteners. These inserts are particularly effective for repairing or strengthening threaded holes in softer metals like aluminum, magnesium, brass, and cast iron, ensuring enhanced durability and functionality in a wide range of applications.

Key Benefits of Metal Threaded Inserts

- Wire thread inserts enhance connection strength and stability, ensuring improved performance at the connection point. Designed for use in metal parts, they allow for greater tightening while reducing the risk of misalignment or slippage, particularly in softer metals like aluminum or magnesium.

- Enhancing wear resistance for connected metal turned components and extending the thread’s service life, particularly for parts that are frequently disassembled.

- In aerospace and other applications, preventing fastening devices from loosening is essential to ensure that parts stay securely attached.

- Repairing damaged internally threaded holes improves tightening performance while allowing the use of the original holes. This helps to prevent further thread damage that could otherwise necessitate the disposal of entire components.

Applications of Metal Threaded Inserts in Automotive Manufacturing

- Engine and Transmission: Threaded inserts are commonly used as engine and transmission mounts to secure the drivetrain. With proprietary designs, they offer custom-built solutions capable of withstanding the vibrations of traditional internal combustion engine (ICE) powertrains. In both electric and ICE vehicles, inserts are also utilized for mounting heat shields, which protect sensitive components and passengers from excessive heat.

- Interior: Threaded inserts are commonly used in seat mountings, seat belts, steering wheels, steering wheel hubs, and airbag assemblies, providing secure attachment points for critical components. They are essential wherever a component needs to be firmly mounted to the vehicle. Additionally, threaded inserts are employed to fasten panels, brackets, and other parts to the dashboard assembly.

- Suspension and Steering Components: Like their use in drivetrain brackets, threaded inserts serve as suspension and steering brackets, securing suspension components like control arms, shock absorbers, and sway bars to the chassis.

- Underbody and Exhaust: Threaded inserts are also utilized in securing exhaust system components. They provide attachment points for oxygen sensor connectors, exhaust system clamps, and support brackets.

Applications of metal threaded inserts in other industries

- Aerospace and Aviation: The first threaded inserts in aviation were used to attach de-icers to airplane wings. Today, rivets and threaded inserts are commonly used in nearly all structural assemblies, as they improve aerodynamics and prevent thread damage that could compromise the structural integrity of the components.

- Boatbuilding: Threaded inserts commonly used in boatbuilding to secure the hull and trim are typically made from corrosion-resistant materials such as brass, coated steel, and other durable metals.

- Furniture: Threaded inserts for furniture are typically crafted from brass or zinc-plated cast metal and come with a hex drive flange, enabling carpenters to install them with a hex drive tool. Additionally, they feature a knife thread designed for fastening into wood, which differs from the metric threads commonly used in machining and metalworking.

- Green Energy: Threaded inserts are designed for durability, making them ideal for green and clean energy applications, such as securing solar panels in wind turbine constructions.

Conclusion

Metal threaded inserts are more than just components – they are key enablers of innovation and reliability in automotive manufacturing. By addressing complex fastening challenges and contributing to the efficiency and longevity of critical systems, these inserts pave the way for safer and more advanced vehicles. As industries embrace new technologies and sustainability goals, the role of threaded inserts will expand, driving progress and supporting the development of cutting-edge engineering solutions.

Selecting the right Metal Threaded Inserts for your vehicle is crucial. At Ravi Products, we specialize in manufacturing high-quality Metal Threaded inserts designed to meet the diverse needs of industries worldwide. With our commitment to precision engineering, superior materials, and robust designs, we provide solutions that deliver unmatched performance and durability. Ravi Products can be your partner in powering innovation and reliability. Get in touch with us on export@raviproducts.com for more information.