Molded Inserts

We are a leading molded insert manufacturing company, providing a wide range of standard and non-standard inserts in a variety of materials, sizes, types, and quantities. We use high grade raw materials to design and manufacture high quality molded inserts as per the specifications. To meet all simple to complex industrial or commercial applications, we also provide custom molded inserts as per custom design/ drawing/ sample/ dimension specification. These inserts are available in various shapes such as rectangular inserts, round inserts, hexagonal inserts, triangle inserts, pentagonal inserts, octagonal inserts, and custom shape inserts.

The offered range of industrial molded inserts is manufactured by our engineers in complete adherence to international quality standards. This range has been in wide demand on the market for its comprehensive features. Apart from molded inserts, we also provide expansion inserts, hex inserts, knurled bush, moulded inserts, press in inserts, self-tapping inserts, special inserts, threaded inserts, and many others.

Our products including molded inserts are available in various grades and specifications to match the most complex requirements of customers. Our extensive knowledge and experience in insert manufacturing has enabled us to carve out industry-specific molded inserts which are quality-tested on various parameters. The main characteristics of our molded inserts are their high tolerances and the bright finish that they have.

Material:

- Brass : C3604, Brass IS-319 Type-1, C36000, CuZn39Pb3, CuZn39Pb2, CuZn38Pb2, CuZn38Pb1.5

- Steel : Steel EN1A/EN1AL,12L14, 11SMNPB30, 9SMNPB28

- Aluminium : EN AW-6060, EN AW-6061, EN AW-6082

- Special metal material composition as per customer requirements.

Availability:

In India as well as USA, UK, Australia, Germany, France, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Spain, Sweden, and other European counties.

Surface Finishing:

Any finishing / coating as per customer requirement.

Key Features of Molded Inserts:

Applications of Molded Inserts:

Why Choose Molded Inserts from Us?

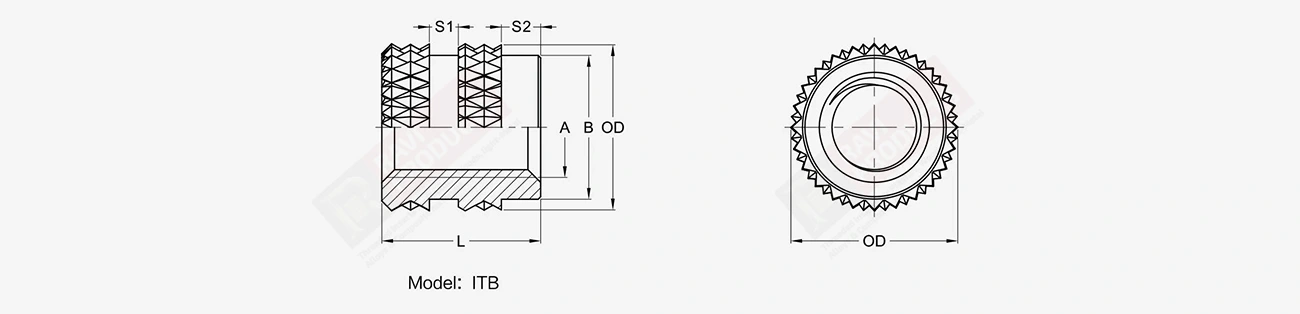

ISO METRIC /Unit:mm

| A Thread size |

L ± 0.13 Insert lengths |

OD Insert diameter |

B ± 0.13 End diameter |

S1 Nom. |

S2 Nom. |

Minor diameter GO./NOGG. |

Core pin 0/-0.01 |

|---|---|---|---|---|---|---|---|

| M3 x 0.5 | 4.77 | 4.77 | 4.34 | 0.78 | 0.78 | 2.515/2.599 | 2.515 |

| M4 x 0.7 | 6.35 | 6.35 | 5.74 | 1.16 | 1.57 | 3.340/3.422 | 3.340 |

| M5 x 0.8 | 7.13 | 7.13 | 6.57 | 1.16 | 1.57 | 4.200/4.334 | 4.200 |

| M6x 1.0 | 9.53 | 8.74 | 8.15 | 1.57 | 2.38 | 5.000/5.140 | 5.000 |

| M10 x 1.5 | 14.27 | 12.7 | 11.84 | 2.38 | 2.38 | 8.500/8.676 | 8.500 |

We are committed to delivering superior molded inserts and exceptional service to meet your business needs. Contact us today to discuss your requirements, or request a quote for molded inserts.