DIN 16903 Knurled Threaded Inserts

We are a globally renowned manufacturer of DIN 16903 knurled threaded inserts for over moulding. We are engaged in manufacturing different types of inserts as per international standards including DIN and many others as per customer requirements. We have an experienced team and utilize modern manufacturing machine tools to provide precision DIN 16903 knurled threaded inserts. We utilize the finest raw materials for manufacturing high-quality DIN 16903 threaded inserts designed for durability, precision, and reliability. DIN 16903 knurled threaded inserts are engineered to meet quality, performance, and value.

We understand that every project has unique requirements. Based on custom specific requirements, our engineering and manufacturing team is ready to collaborate and manufacture custom DIN 16903 knurled threaded inserts. From material selection to design modifications, we ensure customer satisfaction with our personalized solutions. We provide DIN 16903 knurled threaded inserts in a variety of materials, designs, sizes, and threads such as ISO Metric (MM threads), BSP & BSPT (Parallel & Taper Thread), NPT Thread, BSW Threads (Inches), BSF Thread, UNC, UNF Thread, BA Thread, and any threads as per standards and custom designs. Our all products including DIN 16903 are available at competitive prices.

Material:

- Brass : C3604, Brass IS-319 Type-1, C36000, CuZn39Pb3, CuZn39Pb2, CuZn38Pb2, CuZn38Pb1.5

- Steel : Steel EN1A/EN1AL,12L14, 11SMNPB30, 9SMNPB28

- Aluminium : EN AW-6060, EN AW-6061, EN AW-6082

- Special metal material composition as per customer requirements.

Availability:

In India as well as USA, UK, Australia, Germany, France, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Spain, Sweden, and other European counties.

Surface Finishing:

Any finishing / coating as per customer requirement.

Key Features of DIN 16903 Knurled Threaded Inserts:

Applications of DIN 16903 Knurled Threaded Inserts:

Why Choose DIN 16903 Threaded Inserts from Us?

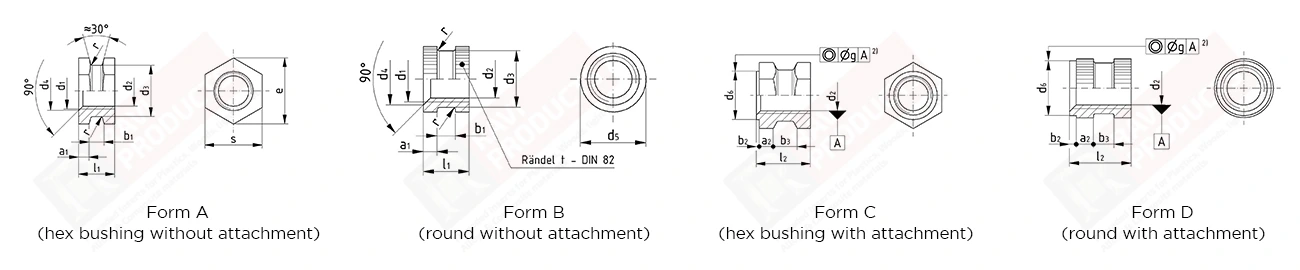

Forms A–D

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | B / D | A / B / C / D | A / C | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 0.8 | 0.9 | 0.9 | 1 | 1.2 | 1.6 | 1.8 | 2 | 3 | 3.5 | |

| a2 | 0.9 | 1 | 1.2 | 1.6 | 1.8 | 2 | 2.5 | 4 | 4 | 5 | |

| b1 | 0.8 | 0.8 | 1.2 | 1.4 | 1.4 | 1.8 | 2.4 | 4 | 4 | 5 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 0.8 | 1 | 1.2 | 1.4 | 1.4 | 2.5 | 3 | 4 | 6 | 7 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | – | – | – | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h12 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h12 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | – | – | – | |

| s | ≈ | – | – | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 |

| e | ≈ | – | – | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

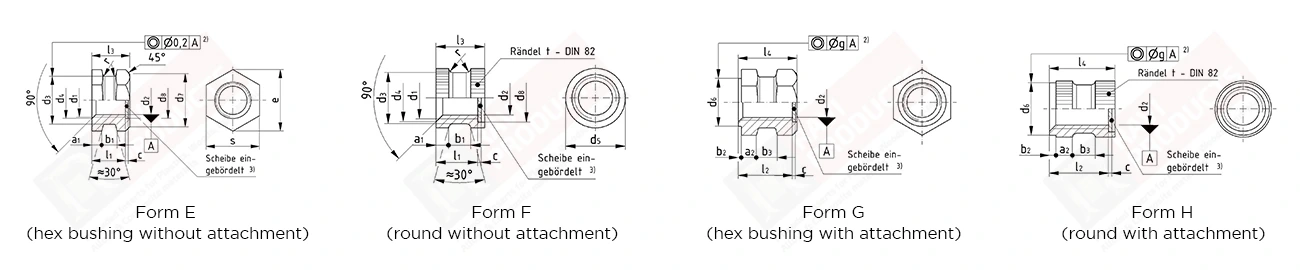

Forms E–H

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | F / H | E / F / G / H | E / G | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.8 | 2.5 | 3 | 3.5 | |

| a2 | 1 | 1.2 | 1.2 | 1.5 | 1.5 | 2 | 2.5 | 3.5 | 4 | 5 | |

| b1 | 1.2 | 1.5 | 1.5 | 1.8 | 2.2 | 2.5 | 3.2 | 3.8 | 4.5 | 5.5 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.5 | 1.6 | 1.8 | 2.2 | 2.5 | 3 | 3.5 | 4.5 | 6 | 7 | |

| c | 0.32 | 0.32 | 0.32 | 0.54) | 0.54) | 0.54) | 0.54) | 15) | 15) | 15) | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 124) | 154) | 184) | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | – | – | 4.2 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| d83) | D11 | 2.6 | 2.8 | 3.2 | 3.8 | 4.5 | 6 | 7 | 9 | 11 | 13 |

| e | ≈ | – | – | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h14 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h12 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h12 | 3.1 | 3.4 | 3.8 | 4.5 | 5 | 6 | 7 | 9.5 | 11.5 | 13.5 |

| l4 | h12 | 4.3 | 4.8 | 5.3 | 6.5 | 7 | 8.5 | 10 | 13.5 | 16.5 | 19.5 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| s | – | – | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | – | – |

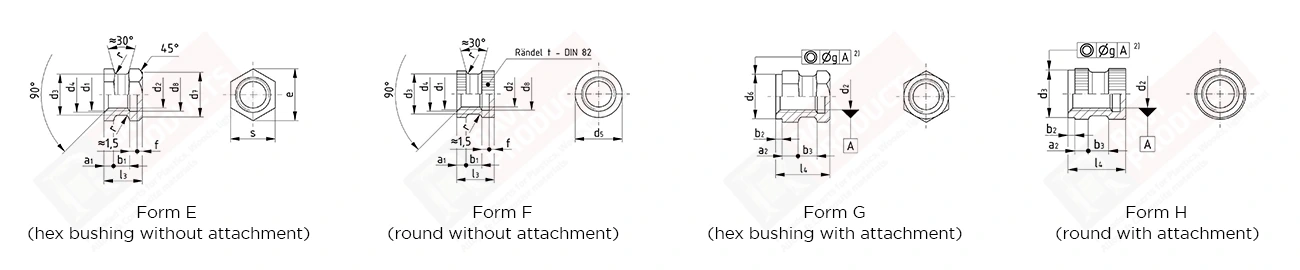

Forms E–H (similar)

| Threaded bushings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | E / F / G / H | E / G | ||||||

| Thread d1 (6H) | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M10 | ||

| a1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.8 | 2.5 | Possible upon inquiry | ||

| a2 | 1.2 | 1.5 | 1.5 | 2 | 2.5 | 3.5 | |||

| b1 | 1.5 | 1.8 | 2.2 | 2.5 | 3.2 | 3.8 | |||

| b2 | 1 | 1 | 1 | 1 | 1 | 1 | |||

| b3 | 1.8 | 2.2 | 2.5 | 3 | 3.5 | 4.5 | |||

| f | (Production-related min. gradient x 1.5 / must be clarified before ordering) |

||||||||

| d2 | H11 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | ||

| d3 | h12 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | ||

| d4 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | |||

| d51) | 4.2 | 5 | 5.5 | 7 | 8 | 12 | |||

| d6 | h11 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | ||

| d7 | 4.2 | 5.5 | 6 | 7 | 9 | 11 | |||

| d8 | + 0.3 | 3 | 3.5 | 4 | 5 | 6 | 8 | ||

| g | h14 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | ||

| l3 | h12 | 3.8 | 4.5 | 5 | 6 | 7 | 9.5 | ||

| l4 | h12 | 5.3 | 6.5 | 7 | 8.5 | 10 | 13.5 | ||

| r | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | |||

| t | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | |||

| s | 5 | 5.5 | 6 | 7 | 9 | 11 | |||

| e | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | |||

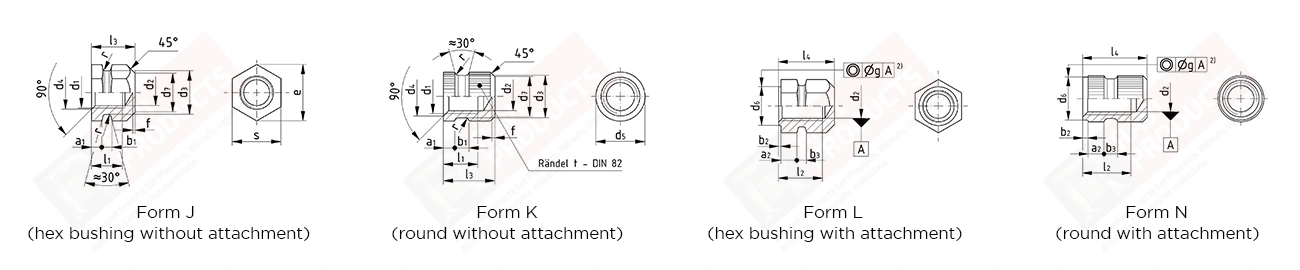

Forms J–N

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | K / N | J / K / L / N | J / L | |||||||

| Thread d1 (6H) | M 24 | M 2.54 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1.2 | 1.4 | 1.5 | 1.5 | 1.8 | 2 | 2.8 | 3.5 | 4 | |

| a2 | 1.2 | 1.5 | 1.6 | 2 | 2 | 2.5 | 3 | 4.2 | 5.5 | 6.5 | |

| b1 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 2 | 2.5 | 3 | 3.5 | 4 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 2 | 2.5 | 3 | 3.5 | 4 | |

| d23) | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | ≈ | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | – | – | – |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | 3 | 3.4 | 3.8 | 4.5 | 5 | 6 | 7 | 9 | 12 | 15 | |

| f | + 0.24) | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| l1 | h144) | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h144) | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h124) | 3.8 | 4.2 | 4.8 | 5.5 | 6.5 | 7.6 | 9 | 12 | 14.2 | 17 |

| l4 | h124) | 5 | 5.6 | 6.3 | 7.5 | 8.5 | 10.2 | 12 | 16 | 19.2 | 23 |

| s | – | – | – | – | 6 | 7 | 9 | 11 | 14 | 19 | |

| e | ≈ | – | – | – | – | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

| g 4) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| r 4) | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t 4) | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | – | – |

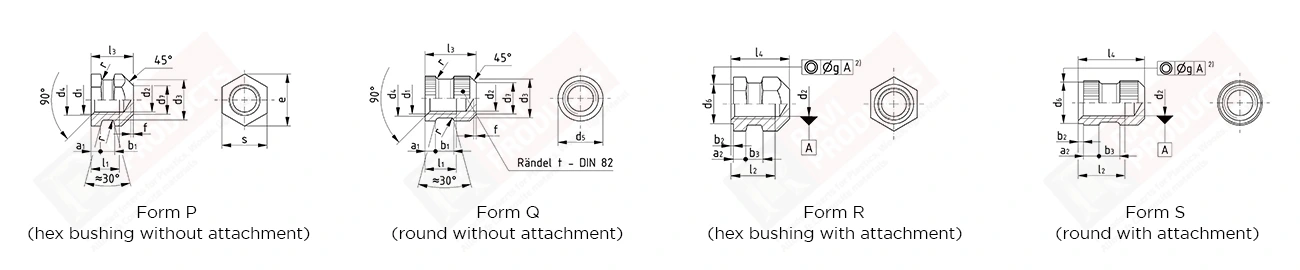

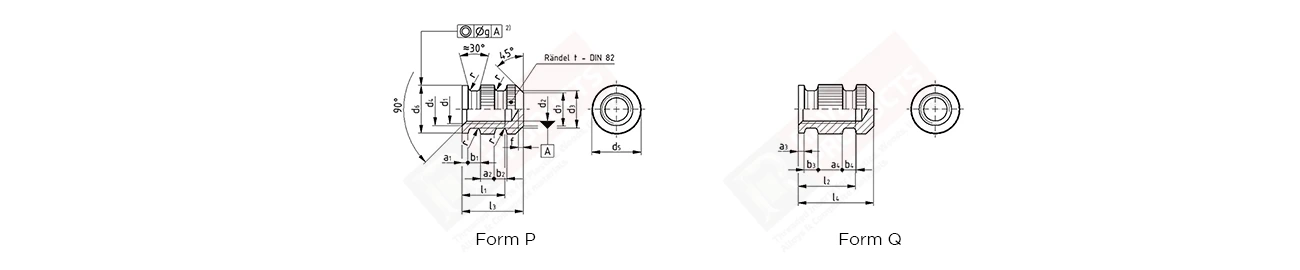

Forms P–S

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | Q / S | P / Q / R / S | P / R | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1.2 | 1.4 | 1.5 | 1.5 | 1.8 | 2 | 2.8 | 3.5 | 4 | |

| a2 | 1.2 | 1.5 | 1.6 | 2 | 2 | 2.5 | 3 | 4 | 5 | 5 | |

| b1 | 1.2 | 1.5 | 1.8 | 1.8 | 2.5 | 3 | 3.5 | 4.5 | 5 | 6 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.6 | 1.6 | 1.8 | 2 | 2.8 | 3.5 | 4 | 5.5 | 6 | 7 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | – | – | – | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | 2.5 | 2.5 | 2.8 | 3.5 | 4 | 5 | 6 | 7 | 10 | 12 | |

| f | + 0.2 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h14 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h14 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h12 | 4 | 4.6 | 5.5 | 6 | 7 | 8.3 | 9.8 | 12.6 | 15 | 17.8 |

| l4 | h12 | 5.2 | 6 | 7 | 8 | 9 | 10.8 | 12.8 | 16.6 | 20 | 23.8 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | – | – | – |

| s | – | – | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| e | – | – | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 | |

Forms T–U

| Threaded bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Form | Tolerance | T | T / U | U | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1.2 | – | – | – | |

| a2 | 1 | 1.1 | 1.3 | 1.6 | 1.8 | 2.2 | 2.8 | – | – | – | |

| a3 | – | – | – | – | 1 | 1 | 1.2 | 1.5 | 1.5 | 2 | |

| a4 | – | – | – | – | 4 | 4.5 | 5 | 6 | 8 | 10 | |

| b1 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.2 | 2.7 | – | – | – | |

| b2 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.2 | 2.7 | – | – | – | |

| b3 | – | – | – | – | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| b4 | – | – | – | – | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.5 | 4 | 4.6 | 5.3 | 6.6 | 7.8 | 10.5 | 13 | 15.7 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 4.5 | 5 | 5.5 | 6 | 7 | 9 | 10 | 12 | 15 | 18 | |

| d6 | h11 | 4.5 | 5 | 5.5 | 6 | 7 | 9 | 10 | 12 | 15 | 18 |

| d7 | 3.4 | 3.6 | 3.8 | 4.5 | 5 | 6 | 7 | 9 | 12 | 15 | |

| f | +0.2 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| l1 | h14 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | – | – | – |

| l2 | h14 | – | – | – | – | 8 | 10 | 12 | 16 | 20 | 24 |

| l3 | h12 | 5.2 | 6 | 7 | 8 | 9 | 10.5 | 12.8 | – | – | – |

| l4 | – | – | – | – | 11 | 13.3 | 15.8 | 20.6 | 25 | 29.8 | |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

We are committed to delivering superior DIN 16903 knurled threaded inserts and exceptional service to meet your business needs. Contact us today to discuss your requirements, or request a quote for DIN 16903 knurled threaded inserts.