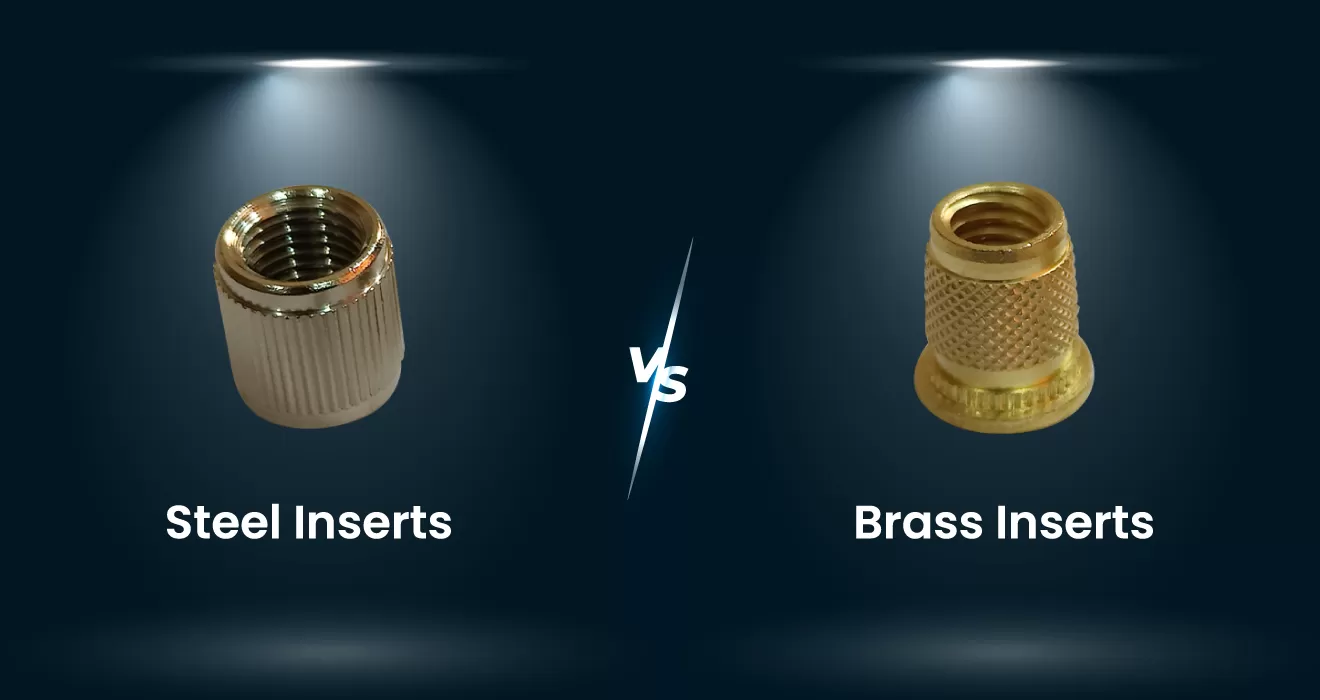

Steel vs. Brass Threaded Inserts: Which one offers better strength and durability?

When it comes to selecting threaded inserts for applications requiring secure fastening, two popular options often come into consideration: steel and brass inserts. Both materials offer distinct advantages, but their performance can vary significantly depending on the specific demands of a project. Understanding these differences is crucial—and that’s where Ravi Products stands out. As a reliable manufacturer and supplier of premium fastening solutions, Ravi Products specializes in both steel and brass threaded inserts, which are meticulously engineered and made from top-quality materials. Their wide range of products is designed to meet the rigorous standards of modern industries, ensuring strength, durability, and reliable performance across a variety of applications.

Overview of Steel and Brass Threaded Inserts

-

Steel:

Steel threaded inserts offer high strength and durability, making them ideal for heavy-duty applications like automotive and machinery. While they heat up more slowly, increasing installation time, steel is more resistant to wear and stress. Despite these challenges, steel is preferred for high tensile strength and long-term durability, especially in extreme conditions or applications with heavy loads.

-

Brass:

Brass threaded inserts heat up and cool down quickly, enabling faster installation with heat or ultrasonic methods. They are easier to machine than steel, reducing production time and tool wear. Brass offers good corrosion resistance in moderate environments and can be recycled to recover material costs. Brass is ideal for quick installation and moderate mechanical loads, making it cost-effective for mass production.

Comparison

-

Thermal Conductivity

- Brass: With 15 times better thermal conductivity than steel, brass is ideal for heat and ultrasonic installation methods. It cools quickly, ensuring better positional accuracy and preventing the insert from floating during installation.

- Steel: Steel threaded inserts have lower thermal conductivity, resulting in slower heating and cooling. This extends installation time, and they may need to be braced with molten plastic to prevent floating, potentially compromising the assembly.

-

Strength and Durability

- Brass: Brass threaded inserts are suitable for moderate loads but have lower strength than steel, making them ideal for applications where high strength is not critical.

- Steel: Steel threaded inserts offer superior strength and high tensile strength, making them ideal for high-stress environments with heavy loads and vibrations. They provide better wear resistance and long-term durability.

-

Machinability and Cost

- Brass: Brass is easier to machine than steel, reducing manufacturing time and tool wear, and making it more cost-effective. Brass scrap can also be resold, providing cost recovery after production.

- Steel: Steel, especially stainless steel, is harder to machine, leading to higher tooling costs and longer production times. While stronger, steel inserts have higher manufacturing costs and little scrap resale value, making them less cost-effective than brass.

-

Corrosion Resistance

- Brass: Brass offers good corrosion resistance to non-oxidizing acids, petroleum products, and mild alkaline solutions but is not suitable for strong alkaline solutions like hydroxides or cyanides.

- Steel: Stainless steel is highly corrosion-resistant, especially in harsh chemicals, acids, or extreme weather. However, it may need passivation (e.g., citric or nitric acid) to maintain its resistance, particularly in austenitic stainless steel.

-

Strength-to-Weight Ratio

- Brass: Lighter than steel, brass threaded inserts are ideal for weight-sensitive applications. Though strong, brass is more suitable for lighter duty use than steel.

- Steel: Steel threaded inserts are heavier than brass, but their higher strength-to-weight ratio makes them ideal for applications requiring maximum load-bearing capacity and strength overweight concerns.

-

Cost-Effectiveness

- Brass: Brass threaded inserts are more cost-effective than stainless steel due to easier machinability and the ability to recover material costs from scrap. However, they are less suitable for high-strength applications.

- Steel: Steel threaded inserts are costlier than brass due to higher machining and tooling costs, but their strength and durability in tough environments make them worth the extra investment for high-performance applications.

Industrial Applications

When to choose Steel Threaded Inserts?

- Steel inserts are ideal for aggressive marine environments, with grades like the 316 series outperforming brass in fast-moving currents due to superior corrosion resistance. However, grades such as 303 have reduced resistance in seawater.

- Additionally, austenitic stainless-steel grades (302, 304, 316) are FDA-approved for food contact, making them the preferred choice for industries like food and beverage processing, where hygiene, durability, and safety are essential.

When to choose Brass Threaded Inserts?

- Both hot and cold-water industrial systems, as well as residential potable water systems, are perfect applications for brass inserts. They also perform well in certain marine environments, including brackish water and seawater with low to moderate currents, naturally forming a protective green patina that enhances corrosion resistance.

- In cryogenic applications, brass threaded inserts can replace 300 series stainless steel in low-temperature environments. Nickel-plated brass threaded inserts are used in gears, bearings, and plumbing fixtures to enhance corrosion resistance and appearance, ensuring both durability and aesthetic appeal.

Conclusion

In conclusion, the selection of steel or brass threaded inserts depends on the particular application. Steel Threaded Inserts offer superior strength and durability for high-stress environments, while brass threaded inserts are more cost-effective and ideal for lighter-duty applications with quicker installation. Both materials have distinct advantages, and understanding the project’s needs will guide the best selection. With Ravi Products, businesses can find high-quality inserts tailored to their requirements.

Looking to choose the right steel or brass threaded inserts for your application? At Ravi Products, we offer a wide range of precision-engineered steel and brass inserts designed to meet diverse industrial needs. Whether you prioritize strength, corrosion resistance, or long-term durability, our expert team can help you select the ideal solution. Request a Quote to discuss your project requirements and get a customized quote!