Threaded Inserts for Metal – How to select the right one based on industrial needs?

Threaded Inserts for metal play a crucial role in enhancing the strength, durability, and reliability of threaded connections across various industrial applications. From automotive and aerospace to electronics and furniture manufacturing industry, selecting the right threaded insert ensures optimal performance and longevity. Factors such as material type, thread size, installation method, and load-bearing capacity must be carefully evaluated to meet specific industrial requirements. At Ravi Products, we provide high-quality metal threaded inserts designed to suit diverse applications, ensuring precision, efficiency, and superior fastening solutions.

Types of Threaded Inserts of Metal:

- Hexagonal Inserts (Types NFPA, NFPC)

- Blind Threaded Inserts (Types IBA, IBB, IBC)

- Self-locking Blind Threaded (Type IBLC)

- Thru-threaded (Types ITA, ITB, ITC)

- Knurled Spacers (Types STKA, STKB, STKC)

- Tapered (Types IUA, IUB, IUC)

- Flanged (Type PFLA, PFLB)

- Straight Wall (Types IUTA, IUTB, IUTC)

Key selection criteria for industrial threaded inserts of metal

Choosing the right threaded inserts for a specific application involves careful consideration of several factors, including:

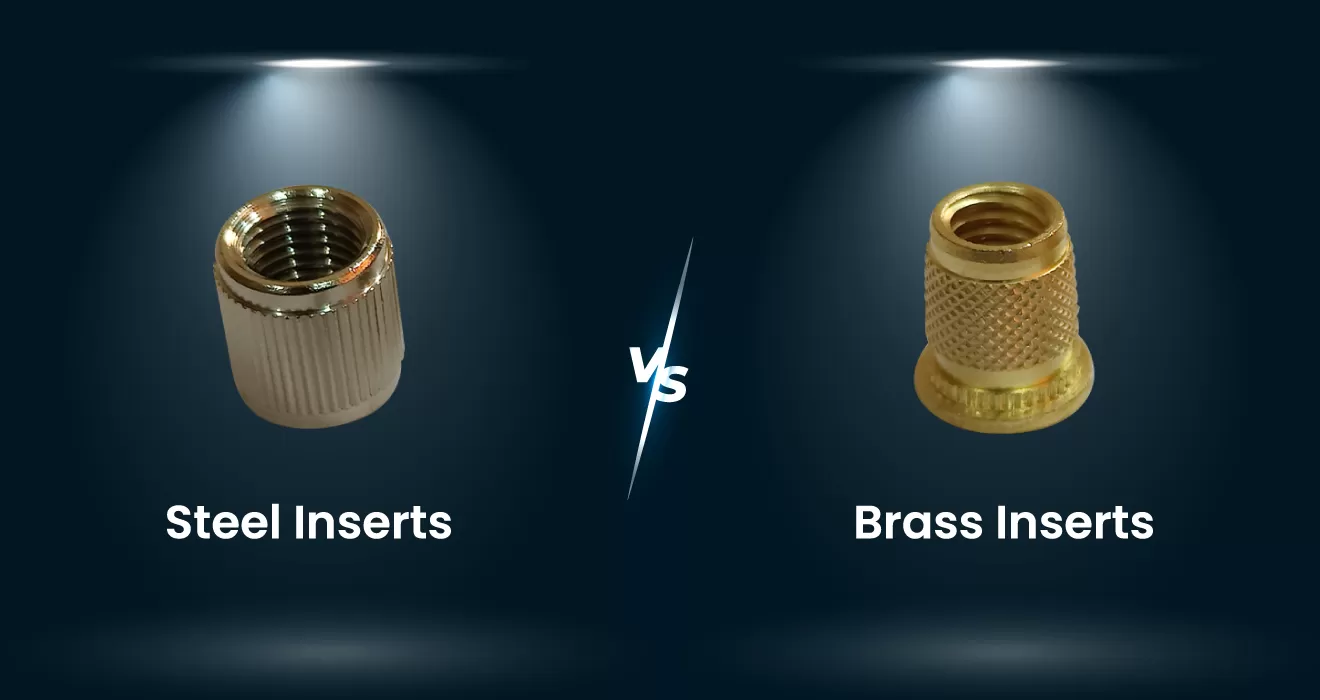

- Material: The material of a threaded insert plays a crucial role in determining the strength and durability of the connection. Common options include steel, brass, aluminum, and plastic, each suited for different applications. When selecting the right insert material, consider the material it will be installed into, along with the expected conditions and load requirements. Choosing the appropriate material ensures a secure and long-lasting connection.

- Size: The threaded inserts must be properly sized to fit the hole where it will be installed. Accurate measurement is essential, as an insert that is too large or too small can compromise the strength and security of the connection.

- Thread configuration: The thread configuration of a threaded insert is crucial for ensuring a strong connection. Choose an insert with a thread pitch and design that match the type of screw or bolt being used, whether it’s a sheet metal screw or a standard bolt, to achieve a secure and reliable fit.

- Installation method: The installation method of a threaded insert is an important factor to consider. Some inserts require a press for installation, while others can be installed using pliers or a threaded insert tool. When choosing the right method, take into account the available tools, resources, and accessibility of the installation area to ensure a smooth and efficient process.

- Strength requirements: Lastly, evaluate the strength requirements of the connection. Will it be exposed to heavy loads or stress, or is it intended for lighter duties? These requirements will guide your choices for the size, material, thread configuration, and installation method of the threaded insert to ensure it can handle the demands of the application.

Industry Specific Applications

Once you recognize the versatility of threaded inserts, the potential applications become clear. This is why threaded inserts are widely used in manufacturing, assembly, construction, and repairs. Here are few industries that depend on threaded inserts:

- Aerospace and aviation: The first threaded inserts were used to attach deicers to airplane wings.

- Automotive: Inserts are widely used in car bodies, including wellnuts with rubber components to reduce vibration, and inserts that secure both metal and plastic body parts.

- Boatbuilding: Threaded inserts are used in wooden and fiberglass boats to secure the hull and trim. Made from materials like brass, coated steel, and other corrosion-resistant materials, these inserts ensure durability and strength in marine environments.

- Furniture: As discussed with wooden furniture, inserts are also used to attach metal to wood, join plastic components, and support various other furniture manufacturing and repair applications.

- Appliances: Threaded inserts are used in many household appliances to secure components such as plastic covers and circuit board controls.

- Green energy: Threaded inserts are designed for durability and are frequently used in green energy applications, such as securing solar panels and constructing wind turbines.

Conclusion

For any inquiries regarding metal threaded inserts, our team is ready to assist you in finding the right solution for your industrial needs. Whether you require guidance on selection, or application support, or have specific requirements, we are here to help. Feel free to reach out via email at export@raviproducts.com or request a quote.

FAQs

-

What Type of Insert Is Right for My Application?

Threaded inserts come in a variety of materials, with brass being the most common choice. However, alternatives such as aluminum and stainless steel are also available, offering a lead-free option. These inserts are typically used in thermosets or thermoplastic materials.

The choice of material plays a crucial role in the durability, longevity, and corrosion resistance of threaded inserts. They are particularly well-suited for use with plastic or soft wood applications. Stainless steel and aluminum inserts provide enhanced strength while being lighter than brass. Additionally, they align better with sustainability regulations, making them an eco-friendlier choice.

-

What Size Threaded Insert Do I Need?

When selecting a threaded insert, size is another key factor. Standard inserts for plastics range from ⅛” to 9/16” in diameter and ⅛” to ⅝” in length, with thread sizes from #0-80 to ⅜-16. This wide range ensures compatibility across various industries, including electronics, automotive, aerospace, defense, medical, industrial, and recreational equipment.

-

How to Repair Threaded Inserts in Wood?

To fix a loose threaded insert:

- Remove the insert

- Dampen a paper towel and place it in the hole.

- Apply metal-compatible glue to the insert’s threads.

- Remove the paper towel.

- Reinsert the insert using an insertion tool.

- Let the glue dry and harden.

-

How to Remove a Threaded Insert?

To remove a threaded insert, you will need a threaded insert removal tool.

Here’s how it’s done:

- Check the insert. If it is not lying flush with the surface, a removal tool will do the trick

- Apply the removal tool, placing it on top of the threaded insert. Line the guide shaft up with the middle of the hole and fasten it into place using the latch. Turn the tool counterclockwise, allowing the blade to cut into the upper part of the insert

- At a certain point, the insert will start to loosen. Continue to turn the shaft while pulling the insert out of the hole

- Check the hole for any residual shavings. If any are present, wipe these with a cloth or rag to remove